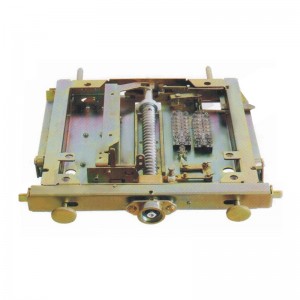

Outline and installation dimension

1、DPC-4A-450 Chassis truck outline and insolation dimension (match VD4)

| Product name | 650mm Chassis truck |

| Material | Iron |

| Shape | Rectangle |

| Size | 650mm depth |

| Color | Silver |

| MOQ | 1pcs |

DPC-□-□/G/S chassis truck

DPC chassis truck mid-door interlock function:

A. DPC-D-EI/G chossis truck

This type only add door closing operation, the handle of chassis could be shookonly when the cabinet door closed. Don’t need to modify the cabinet door

B. DPC-EJ-EI/S chassis truck

This type add locking on item A. when the handcart moves away from testing pos-ition, the door will be locked, which can be opened again only when the hand-cart back to the testing position. The cabinet door need to be changed.

DPC-□-□/H Chassis truck

This type can interlock between two or more chassis.Once one chassis is in working,The others will fail to work. It is suitable for interlock of dual-power supply cabinet. The user only needs to open two holes on the cabinet door, recommended size:φ30

Mid-door interlock assembly drawing

Program interlocked chassis (Two-input-one interlocking device

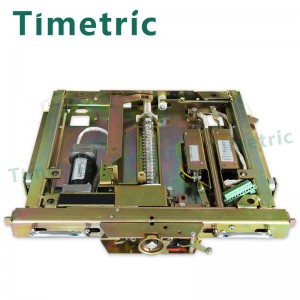

Overview of DDPC-4-800 electric chasis

To meet the development of the power switching devices ond the new demand of power divisions, we have developed the electric chassis which fills the domestic blank and achieves national patent for invention. To maintain the style of the original chassis used in the center console.The electric chassis is improved with an electnc mechanism from the original chassis 650#, 800#, 1000# and 24KV# series, which maintains the character of the original chassis and achieves the electric operation of the chassis’s working position and test position. Therefore, the electric operation and manual operation do not need to be switched, which satisfies the requirements of programmed operation in the power system.

Introduction

The controller of chassis can achieve the control and protection for the electric mechanism, the controller can brake the motor immediately when the motor-driven drive motor is blocked (for example, installaiion is not in place or mechanism is stuck ) and reach the proledton condition ond reversely drive motor to release the stuck stale of the chassis

Operating Instructions of the electric chassis

●Only when fhe grounding switch ond circuit breaker are at opening slates, the chassis is allowed to be swung in ond oul.

●When the chassis is equipped with manual priority function. under manual operation stalus.the electric button for swing in and out is pressed without any action.

●When the chassis is not at working position and test position under natural stale, if ilts needed Io be swung in fhe working position by electric operation, fhe chassis muse be swung in the test position by manual or electric operation first, then il is moved to the working position by electric operation

●When it needs manual operation after electric operation, the handle must be inserted into it and rotate it about 80°. then reversely rotate it about 30*

●In case that the handle of chassis can not be pulled. to observe whether the angle of the screw rod is in the correct position.

● If the operation needs an emergency stop during electric operation process, or there is fault which is solved, just press the reset button.

Motor parameters

●Power voltage: AC/DC220V.AC/DCl10V

●Rated motor volage: DC220V,DCl10V

●Rated motor power: 200W

●Rated motor torque: 260N/m

●Motor rotation speed:50r/min

Control Instructions of the chassis

●The control logic

●The electric pushing operation is allowed when the interlock signal is satisfied.

●During the electric operation, when input the pushing in/out command and the controller still performs the original operation.

●During the electric operation, if press pushing in/out button on the panel at the same time or the interlock signlisinvalid the contrller willstop operation.

●When the locked-rotor prolecioncondition is satisfied, the controller let the mechanism rotate reversely for 200ms after stopping the mechanism; 15s before swinging in, the locked-rotor protection current setting value is set to 1.2Aand 4A after 15s;7s before swinging out,itis set to 4A,and 1.2Aafter 7s.

●The electric pushing in/out operation is imited within 80s. When the time is up and the chassis is not in the position,it will stop and alarm.

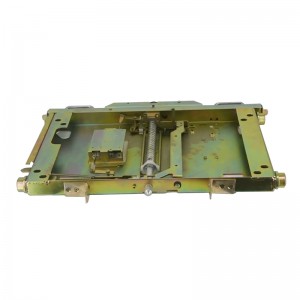

General description

Chassis truck is mainly used to hold circuit breaker, transformer and other components in the withdrawable switchgear as auxiliary operation of components with busbar, when operation with busbar. When operation with internal mechanism of circuit breaker and other interlock mechanism of mid-placed cabinet, it can satisfy the interlock requirement of “5 preventions” stipulated in GB3906.

This interlocking device is mainly used for interlocking to prevent two handcarts from entering the working position at the same time. The main interlocking function is: two chassis vehicles are controlled by one key. When any one of the chassis vehicles is in the working position, the key cannot be removed, the other chassis vehicle does not have the key to unlock, the handle cannot be inserted, and the chassis vehicle cannot Shake to prevent it from entering the working position.

Product Description

Chasis truck mainly used for switch equipment to install circuit breaker, transformer and other components, push and exit it ,play a supplementary role in connecting the components with the busbar.

When chasis truck works with the internal mechanism of circuit breaker and other switchgear interlocking mechanism ,can meet the interlock requirement of GB3906-five prevention.

1.In closing state, when handcart in working or isolated position, and with handle operating, the handcart won’t move, so that to prevent to pull handcart on- load.

2 .When handcart in working position, EK6 earthing switch can’t close, to avoid closing earthing switch.

3 .When handcart back to isolated state, after EK6 closing, the handcart can’t be moved to working position to prevent closing with earthing wire.

4.Once handcart is away from isolated position, when push the handcart with handle to working position, during the way, can’t carry on closing operation.While after reached to working position, closing operation can be made.

5.After handcart getting into cabinet, as long as handcart is not in isolated position, it can’t draw out from the cabinet.